Blueback billboard poster printing

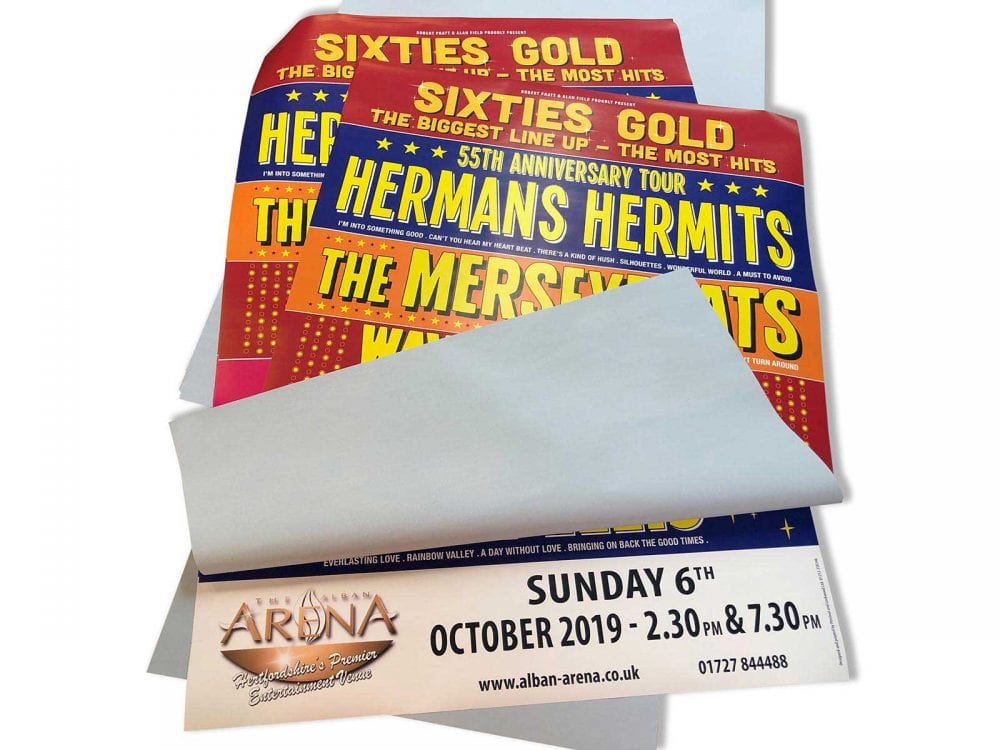

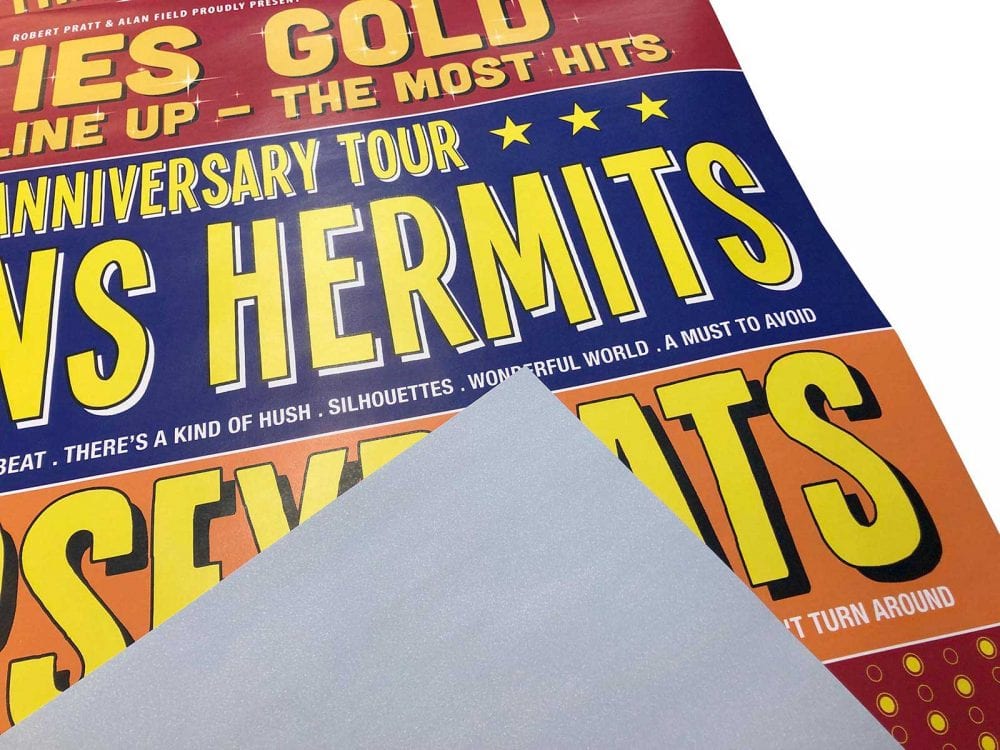

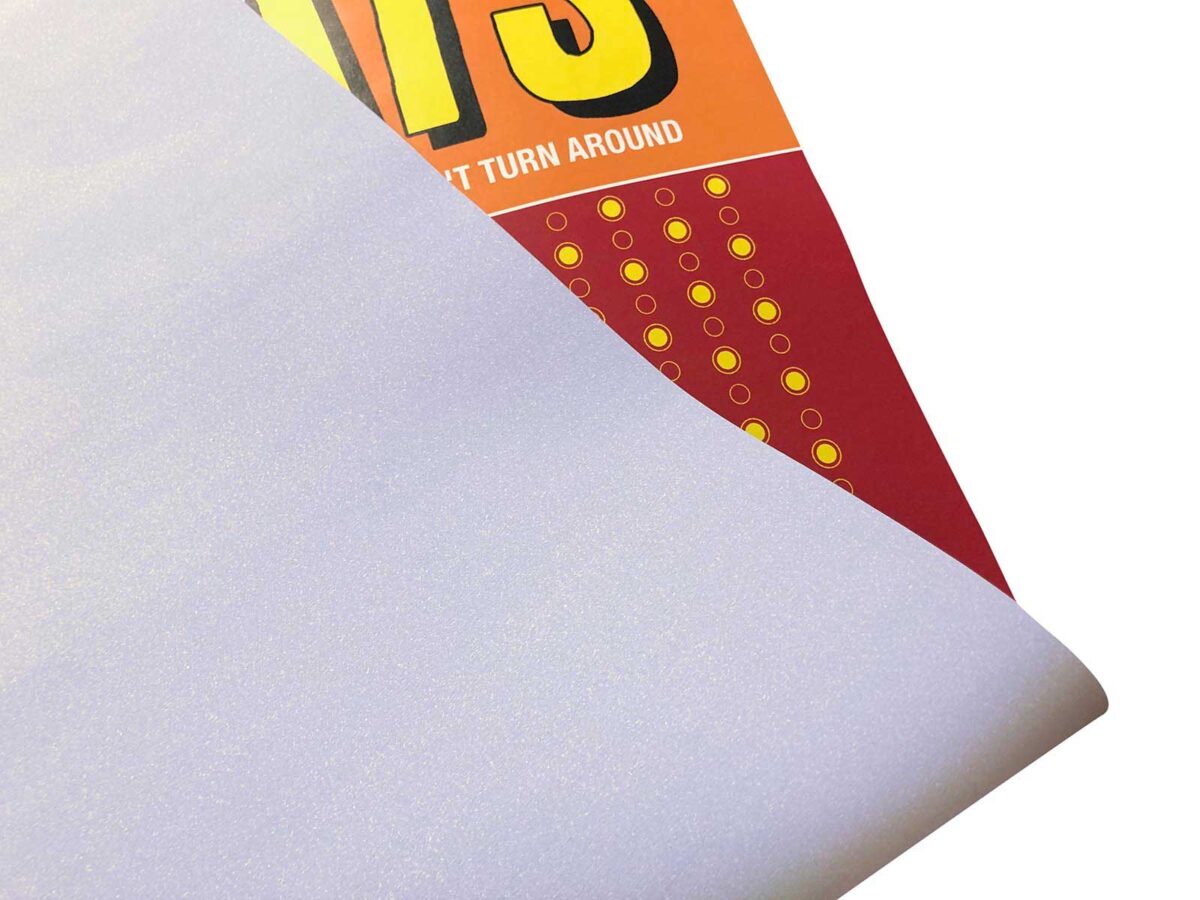

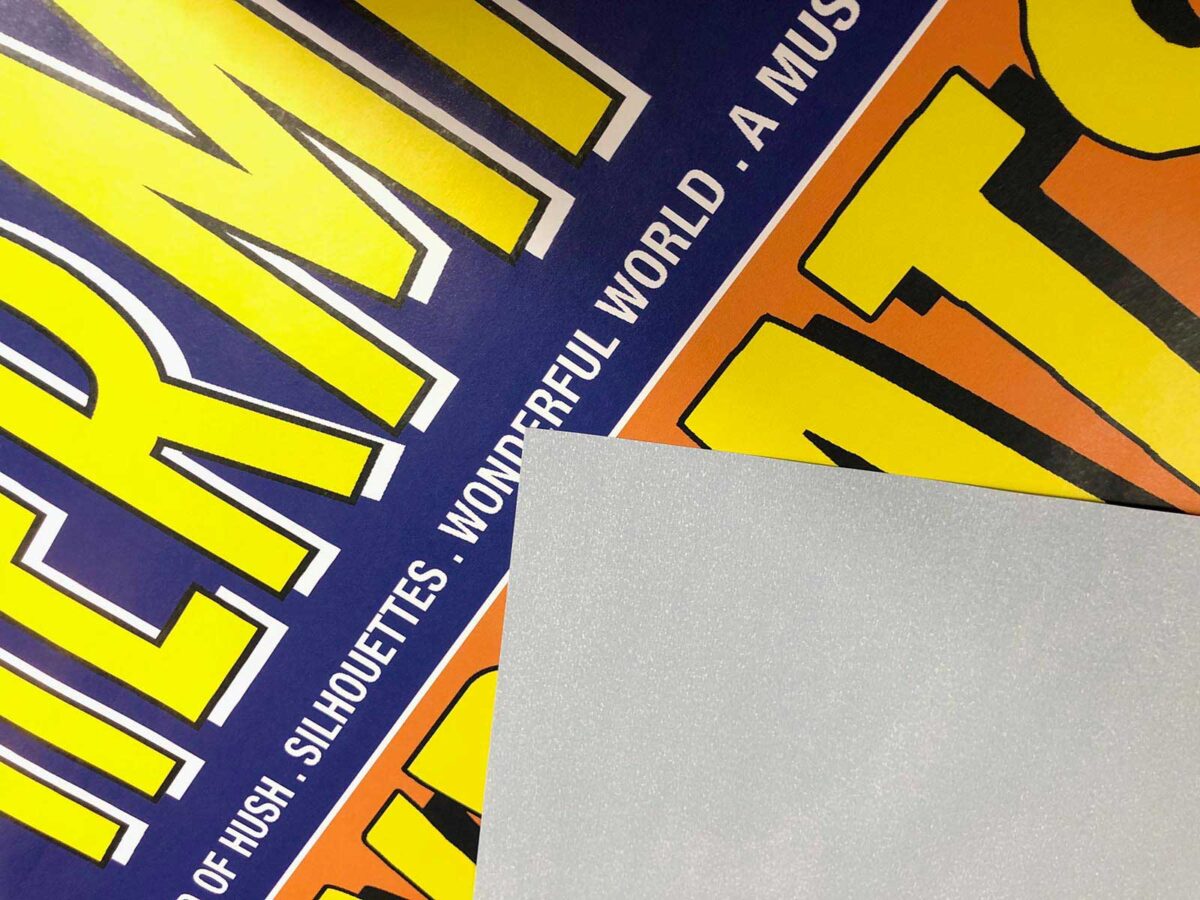

Our billboard poster printing service is perfect for billboard wallpaper or cost-effective small-medium runs of fly posters. Blueback posters have a blue backing. The coloured backing enables them to go over existing billboard graphics with minimal show-through of the old poster underneath.

Traditional billboard printers

Custom billboard printing isn’t as popular as it once was due to the increase in digital signs. However, much of the older print factories have moved on into other directions because of less demand. Even though there is less demand, we have been producing billboard signage for many years. Because we use the latest digital printing technology now means that we can produce a one-off high-quality billboard or 100’s at a time with the same ease.

Large billboard poster printing

We print large billboards to any size. The most popular billboard size is 48 sheet which equates to (6096mm x 3048mm) or 240 inch s 120 inch.

‘Sheet’ is an old fashioned measurement of billboards measured by how many sheets it took to paste a billboard.

Fly poster printing

We can print fly posters at any size and quantity. Fly posters are perfect for pasting up around town to promote a new concert or upcoming gig. We print or concern posters in super full quality onto blue backed poster paper. We print all our custom fly posters in super full colour and photographic quality, meaning we can print any design you create.

Standard Billboard poster sizes

| Poster | Size | Safe Area |

| More O Ferrall / Adshel | 1800mm x 1200mm | 1760mm x 1160mm |

| Decaux | 1750mm x 1185mm | 1710mm x 1160mm |

| Viacom | 1800mm x 1200mm | 1755mm x 1160mm |

| Primesites | 1800mm x 1200mm | 1720mm x 1160mm |

4 Sheet based

| Poster | Description | Size Inches | Size MM |

| 4 Sheet Poster | This size is usually referred to as a 4 sheet poster and is regularly used for outdoor advertising | 60″x40″ | 1524mm x 1016mm |

| 12 Sheet Poster | A poster comprising three 60×40 sections joined. | 60″ x 120″ | 1524mm x 3048mm |

| 16 Sheet Poster | A poster comprising four 60×40 sections joined. | 120″ x 80″ | 3048mm x 2032mm |

| 32 Sheet Poster | A poster comprising eight 60×40 sections joined. | 120″ x 160″ | 3048mm x 4064mm |

| 48 Sheet Poster | A poster comprising twelve 60×40 sections joined. | 120″ x 240″ | 3048mm x 6096mm |

| 96 Sheet Poster | A poster comprising twenty four 60×40 sections joined. | 120″ x 480″ | 3048mmx 12192mm |

| Small Format Poster | |||

| Quad | A regular size used outdoor and indoor and largely in cinema industry | 30″ x 40″ | 762mm x 1016mm |

| D. Royal | A regular size used mainly by British Rail. | 40″ x 25″ | 1016mm x 635mm |

| D. Crown | A regular size used mainly by in-store promotions. | 30″ x 20″ | 762mm x 508mm |

1 review for Blue Back Poster Printing

ACE ELECTRICAL NW LTD. (verified owner) –

Would highly recommend Banner World as there product professionalism and customer service is outstanding, very pleased with the product & detail ?

Thanks guys look forward to doing business with yourselves in the near future.

Based on 113

Google Reviews