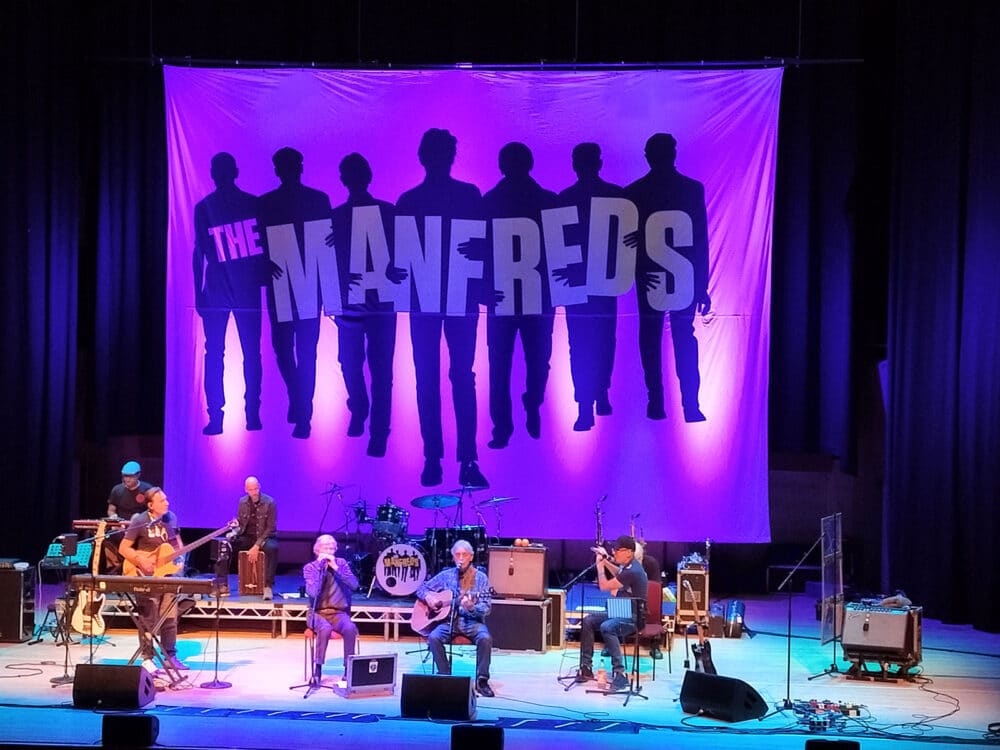

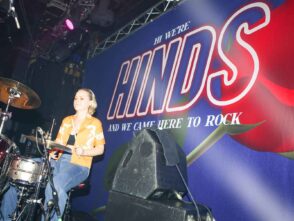

Band banners, backdrop banners, promotional stage scrims for bands and stage backdrops are custom-made and printed to any size to suit your needs. Our printed backdrops give incredible colour reproduction under any lighting conditions. No matter the size of your band’s venues, if you are performing in a small pub or a big theatre, our custom backdrops for bands will do the job.

We know the live entertainment experience should be a memorable one. That’s why we specialise in creating high-impact festival-quality custom backdrops for bands that are built to last, no matter how lairy tour-life gets. Our premium fabric band banners come printed on a resilient tight-weave knit that’s completely flame retardant without sacrificing beauty.

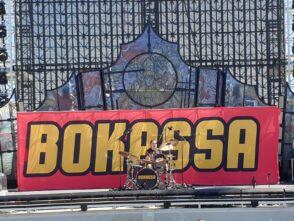

At Banner World, we specialise in crafting high-quality, custom-printed band backdrops tailored to our clients’ specific needs and preferences. Our band backdrops serve as impressive promotional visual anchors, connecting audiences with the band’s name and brand while also creating engaging content that fans can share on various social media platforms, such as Instagram, Facebook, YouTube, and Twitter. Banners and Backdrops are are great marketing tool.

Our commitment to sustainability sets us apart in the industry; we use fully recyclable polyester to create our backdrops, distinguishing our products from cheap promotional PVC banners. Our display-grade, synthetic polyester material produces vibrant, full-colour prints with photographic-quality images, ensuring that your logo, design, and artwork will make a lasting impression. The meticulous manufacturing process enables us to create band backdrops in any custom size and with various finishing options, including pole pockets, eyelets, and stitched hems.

Designing your band backdrop with us is a breeze, thanks to our easy step-by-step ordering process. Simply choose your custom size, enter your preferred finish, upload your artwork, and provide any notes for our pre-press team, such as background colour and logo positioning. By incorporating prominent logos and striking designs, our backdrops can transform any stage, from intimate gigs in clubs and pubs to large-scale productions at festivals and concert venues.

You can also design your band backdrop online. Our online designer is a versatile tool that empowers you to craft eye-catching designs effortlessly. Using our designer, you can select from a vast array of text and background hues to complement your brand or aesthetic. You can also upload logos and images to further personalise your design. Additionally, our library of thousands of scalable clip art and background images provides you with a plethora of options. With our online designer, the creative possibilities are infinite, and you can produce the ideal design for any purpose.

Custom Band Banners & Backdrop Banner Printing

We print your backdrop banner with the artwork you’ve uploaded. If it’s a black background you require, then please set your artwork with a CMYK mix of 10:10:10:100. Our premium backdrop banner printing for bands is ideal to use on stage against a solid surface. Choose our Blockout Band Backdrop if you need to block out all light from behind.

Premium Fabric Backdrops

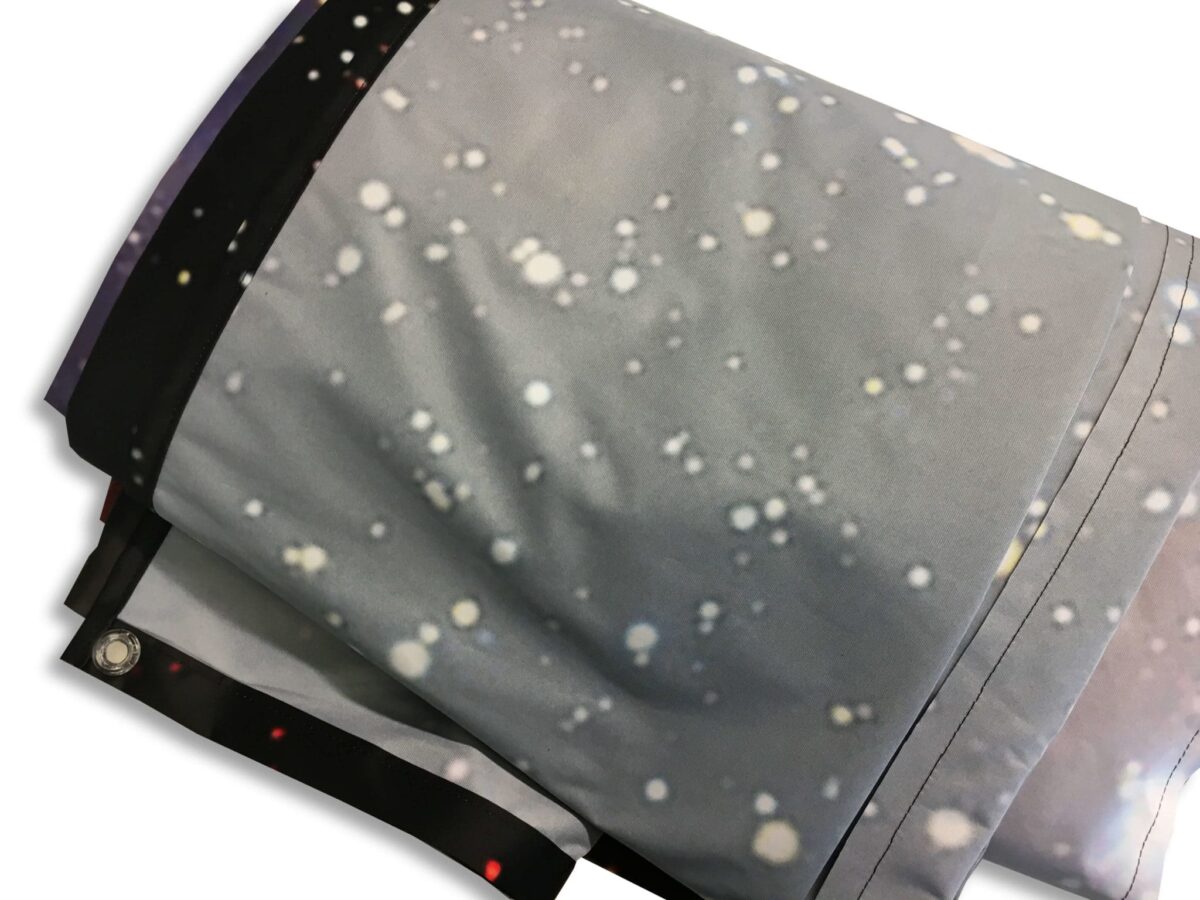

We use a high-quality 210gsm Polyester to produce our Premium Fabric Band Banners, Backdrop Banners, Stage Scrims, Band Scims, Custom Banners for Bands and Stage Backdrops. Our promotional backdrop banners are printed using Dye Sublimation print technology.

The Dye Sublimation process means our backdrops for bands won’t run or fade. To clean, you can wipe smaller areas with a damp cloth or machine wash when required at a low temperature. Roll or fold your band backdrops between gigs to keep them in perfect condition.

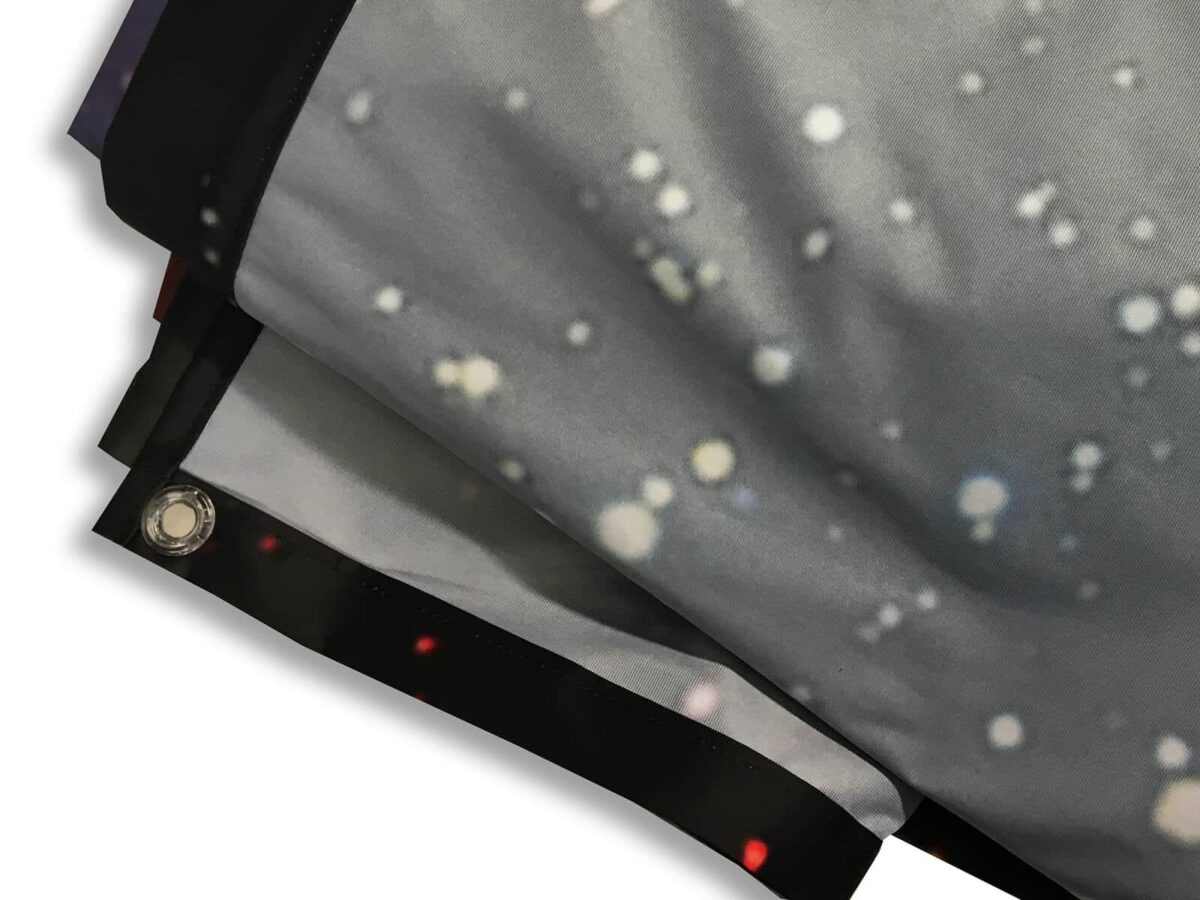

We produce our backdrop banners and stage scrims using the latest printing technology. Once printed, our skilled finishing team take over, carefully adding seams, hems, eyelets and even pole pockets. Standard finishing includes hem and eyelets. We only use specialist quality plastic eyelets in our backdrops, which won’t rust and damage the printed backcloth.

Our maximum print width on premium fabrics is 3 metres. Backdrops and banners for bands larger than this in one dimension will have panels seamed together. We do have alternative materials with a width of up to 5 metres. Double-sided backdrops are also available.

Scrims For Bands

There’s nothing more important for emerging bands than getting your name in front of new audiences. As such, finding the perfect printed stage backdrop or band banner is more than just a throwaway purchase.

The right band banner can add an effortless air of professionalism while getting your name out there and engaging new fans at every gig. Scrims for bands can really help with this!

If you’re a touring musician, the last thing you want is for your signage to let you down. Sure, playing to potential new fans is good but if they can’t remember your name, you’re unlikely to see them again.

Cheap event banners or PVC banners can ruck or decline in quality over time – ultimately impacting your image. Our fabric band banners, backdrop banners, custom made backdrops, and scrims easily roll and fold away, ready to be used again.

Spot a crease? Iron it out on a low heat and watch it disappear. Meanwhile, their lightweight material makes them a dream to pack away and transport to your next event.

Band Backdrop Specification

- Tough 210gsm lightweight polyester fabric

- Flame retardant to BS5867-2: 2008: Type B specification

- Ideal for indoor or outdoor use

- Dye sublimation print for stunning reproduction

- Anti-glare and non-reflective finish

- Machine washable at 30 degrees

- Colour-coordinated stitching

- Maximum size in both dimensions without a join = 2.6m to 2.9m depending on finishing

Stage Banner Prices

We make it very easy indeed for you to know Stage banner Prices! Simply enter the width and height of your Backdrop in the boxes above to see an instant price. You can then add finishing specifications (most of these are included in the price). Prices will change if you order more than 1 backdrop, as we calculate based on the amount of backdrop material used.

Any Design in Full Colour

We print from your artwork and print-ready files – this can be your band logo or other design, including photographic or illustrated backgrounds. Thousands of high-resolution backdrop themes and ideas are available from image banks such as the Adobe Stock Library for minimal cost.

We print these using dye-sublimation technology to provide eye-popping, vibrant colours and photo-quality images. We print fabrics on rolls up to 3.2m wide to provide large seamless panels or combine panels to produce enormous one-piece backdrops and scrims for bands.

High-Quality Materials

Our standard 210gsm knitted polyester fabric used for backdrop banner printing has a tight weave, allowing us to print to an exceptionally high resolution. Therefore even the smallest details will look superb.

Finishing Included

Choose hems and eyelets or pole pockets depending on how you intend to install the backdrop.

Hem and eyelets

Ideal for hanging banners using zip ties, cord or string.

Pole pockets

A top pocket is ideal for using a cable or bungee to hang. Pole pocket at the bottom of the backdrop is the right solution for weighing down your banner and adding some tension.

Why Choose a Fabric Band Backdrop?

- Our band backdrops are lightweight and easily transportable. Roll or fold them up, and you’ll be on your way, minus any creases.

- Band banner a bit messy? It’s nothing a quick wipe clean won’t fix. They’re even machine washable at 30 degrees if things get a little too out of hand on the road.

- Our products are 100% safe and come with a flame-retardant fire safety certificate.

- They’re recyclable and more environmentally friendly than their vinyl PVC counterparts so you can rock out in the knowledge that you’re doing your part for the environment.

- Best of all: they practically pay for themselves when it comes to free promotional advertising

High Quality and Affordable Band Backdrops

Got great ideas but little disposable income? No problem. We are the lowest cost supplier of backdrop printers in the UK. We can print banners and stage backdrops at the best prices possible while maintaining an unbeatable quality. All fabric band banners are fully customisable with hem, eyelets or pole pocket finishing included free of charge. Plus our lightweight, durable and flame retardant material makes them easy to hang, regardless of venue.

We print our backdrops using state of the art Dye sublimation technology. Dye sublimation offers anti-fade and extra longevity. All of our premium backdrops are anti-glare, so won’t reflect light.

Flame Retardancy Certificate

Our Fire Certificate for this product is unique in the industry in that we have our fabrics tested for flame retardancy after printing and finishing. Many venue safety officers will now not accept a generic fire safety certificate if it is just for the base fabric. Tested to the highest UK standards, our backdrops surpass BS5867-2: 2008: Type B.

Our Band Scrims are More Eco-Friendly than PVC Banners

Backdrop Options

We can also make even cheaper band banners and stage scrims from standard PVC or Mesh banner material. Although these do save on initial cost, larger cheap band banners are more difficult to pack away. They also take up more storage room and will not look as good for as long.

Our Blockout Band Backdrops use the same high-quality material as our Premium Backdrops, with the addition of a layer of black resin on the back to block out all light from behind.

Satin Backdrops add extra sheen and glitz for scrims for bands.

Need a Backdrop Banner Stand? Check out our new product here.

Design Guide for Band Backdrops

Set your dimensions correctly

Set the correct CMYK colour settings

Position of eyelets on your Printed Band Banners

Pole Pockets on Band Banners

We can finish your band banners with pole pockets if required. Please ensure that your artwork is the correct dimensions of the of the size you require. Standard scaffold tubes require a 150mm flat pocket size to fit comfortably with plenty of space as to not cause to much tension on the pocket seam. Solid colour/ background images or patterns are fine just not text or vital information.

Check here for more information on pole pockets and how to design for them.

Band Banner Design Principles

For band banner design and scrims for bands it is always important to consider viewing distances. Always create your artwork to give the highest possible impact. Contrasting colours will give your banner much more clout than washed out subtle colours.

A single band logo is usually ideal for a band backdrop design, or even a step and repeat design.

Consider the size of your text. From a distance, larger text is easier to read. Use upper and lower fonts. Road signs are all in upper and lower type rather than all capitals. Subconsciously your eyes will read upper and lower (sentence case).

Font type… Clearer fonts work better than fancy, stripy or script fonts. Look at the backdrops for the big performers – they often just display the band name.

Cramming every little bit of information onto your band backdrop banner and scrims for bands is not a good idea. Less is more. Remember to use clear areas of space and give your design space to breathe. The best backdrops are always simple and straight to the point.

Consider adding a QR Code on your design for scrims for bandswhich will link to your band’s website or social media page.

Speak to our knowledgable Customer Service Team on designing your band banner or backdrop.

Materials and Sustainability

At Banner World, we prioritise sustainability and quality in our products. That’s why our band backdrops are printed on fully recyclable polyester, ensuring a sustainable and eco-friendly solution for your band. Our display-grade polyester material is not only durable but also not to be confused with cheap PVC banners, which do not offer the same advantages of sustainability and quality.

Customisation and Design

We understand that every band has its unique style and needs. Therefore, we provide full-colour custom printing, which allows you to showcase your artwork at photographic quality. During the easy step-by-step ordering process, you can upload your artwork and provide notes about the background colour, logo positioning, and other design elements to our pre-press team. Some tips for designing your backdrop include making your logo big and bold and placing it above the centre to ensure the band members or equipment does not obstruct it on stage.

Uses and Benefits

Our band backdrops offer a variety of uses and benefits for your band, whether it is for concerts, clubs, pubs, or festivals. One significant advantage is their effectiveness in promoting your band on social media platforms such as Instagram, Facebook, YouTube, and Twitter. Custom backdrops create a buzz about your band’s name and brand and allow your fans to promote you through their posts and interactions. Using a backdrop during live shows adds an element of excitement and energy to your performance, making it a memorable experience for your audience.

Band backdrops are versatile, with options for use in different venues, with various lighting and sound setups. They’re also great for events like weddings or themed parties, where you want to create a specific atmosphere or style. With instant pricing and an easy-to-navigate ordering process, you can customise your band backdrop to your exact specifications.

In summary, our band backdrops at Banner World offer a sustainable, high-quality, customisable solution for promoting your band and enhancing your live show experience. Get started today by visiting our website and creating the perfect backdrop for your band’s unique style and needs.

Design Tips

We know how important it is to have a visually striking and memorable band backdrop. Here are some design tips to guide you through the process of creating the perfect band backdrop for your performances and events.

Logo Size and Placement

A band’s logo is essential for recognition and promoting your brand. We recommend making your logo big and bold in the design of your backdrop. Utilise the full spectrum of colours to make your band stand out and create a lasting impression on your audience. When placing your band’s logo on the backdrop, always make sure that it is above the centre. This ensures that it is not obstructed by the band members or the drum kit as they perform on stage. Remember, the primary goal is to make your logo visible and easily identifiable even from a distance.

Avoiding Obstructions

Band backdrops are often placed on stage, behind the band members and their instruments. Therefore, it is crucial to be mindful of potential obstructions when creating your backdrop. Consider the placement of stage equipment, such as speakers, lights, and mic stands, as well as the position of the band members themselves. To avoid obstructions, keep the essential elements within the top two-thirds of the backdrop. This way, your logo and other vital information will remain visible even when the band is performing.

To make it easier for our clients, we offer an easy step-by-step ordering process for our band backdrops:

- Choose your custom size: Enter the width and height that you desire for your band backdrop. This allows for versatility and customisation to fit any stage or venue.

- Enter your finish: Select the type of finishing for your backdrop, such as pole pockets, eyelets, or stitched hems. This ensures your backdrop is ready for easy installation and professional display.

- Upload your artwork: Provide your design, including your logo and any other necessary elements. You can also add notes for our pre-press team, such as background colour, logo positioning, and any other specific requirements. We also have an online design facility where you can upload logos, add text and have a choice of thousands of vectored clip art.

Our band backdrops are made from fully recyclable polyester material, which is not only sustainable and environmentally friendly but also superior to cheap PVC banners. We print in full color and at any custom size, providing you with photorealistic quality on your backdrop to enhance your performances and social media presence across platforms like Instagram, Facebook, YouTube, and Twitter.

Custom Band Backdrops

At Banner World, we specialise in printing high-quality, fully sustainable, and recyclable band backdrops. Our backdrops are made from synthetic display-grade polyester material, not cheap PVC banners. This ensures that our backdrops are not only eco-friendly but also durable and visually appealing.

Custom band backdrops offer bands an excellent opportunity to create a strong visual identity and gain recognition on social media platforms like Instagram, Facebook, YouTube, and Twitter. Our backdrops are customisable, allowing for a wide range of sizes, high-resolution full colour prints, and any design you desire.

We recommend keeping your logo large and bold, positioning it above the centre of the backdrop to avoid obstruction by the band members and equipment on stage. With our help, your logo can become instantly recognisable, garnering attention and inspiring fans to share your band’s name and brand.

Ordering Process

Step 1: Choose Size

At Banner World, we offer band backdrops in an array of custom sizes to suit events of any scale, from intimate pub performances to large festival stages. You simply need to provide us with the dimensions you require, ensuring the backdrop fits perfectly within your desired venue.

Step 2: Select Finish

Once you’ve chosen the size of your backdrop, you can select the finish that best meets your needs. Options include:

- Pole pockets

- Eyelets

- Stitched hems

Each finishing option serves a different purpose and caters to various setup preferences.

Step 3: Upload Artwork or Design online

The final step in the ordering process is to upload your artwork. Our user-friendly interface allows you to easily attach your design files and provide notes for our pre-press team regarding background colours, logo placement, and any additional requests.

Our online designer is a powerful tool that allows you to create stunning designs with ease. With our designer, you can choose from a wide variety of text and background colours to perfectly match your brand or style. You can also upload logos and images to further customise your design. And if you need even more options, choose from our library of thousands of scalable clip art and background images. With our online designer, the possibilities are endless, and you can create the perfect design for any occasion.

Band Scrims

Your choice of band scrim, venue, festival, or any other requirement is made possible by our easy ordering process. With clear and concise steps, we at Banner World ensure that your event is tailor-made for you, providing an exhilarating experience for everyone involved.

At Banner World, we understand the importance of creating a powerful, memorable visual identity for your band. Our custom printed band backdrops are designed to help you achieve this goal while remaining environmentally friendly and providing excellent value for money.

In addition to band backdrops, we also cater to various businesses, companies, and sponsors, offering a comprehensive range of visually engaging products and services. We are dedicated to providing superior quality backdrops, reliable service, and competitive prices to help you make an impact, whatever your needs or venue. So trust Banner World to bring your band’s visual identity to life, and watch your image take center stage.

Top Quality Scrims for Bands

At Banner World, we specialise in creating custom printed band backdrops, tailored to our clients’ unique vision and artwork. Our band backdrops are made from fully recyclable polyester, ensuring a sustainable and eco-friendly product. Unlike large vinyl banners, our backdrops are crafted from high-quality synthetic display grade polyester material, setting us apart from other cheap PVC alternatives.

Our backdrops are designed to elevate your band’s presence across various social media platforms such as Instagram, Facebook, YouTube, and Twitter. Loyal fans will enjoy promoting your band’s name and brand while creating a buzz around your performances.

Uses in Various Venues

Our band backdrops are suitable for a wide range of venues, from intimate clubs and pubs to larger festivals and concerts. With custom sizing options available, you can be assured that our backdrops will fit perfectly on stage, regardless of the size of your performance space.

When designing your custom backdrop, we recommend making your logo prominent and eye-catching. Place your logo above the centre to ensure it remains visible even when performing on stage or behind a drum kit. Our full-color printing allows you to incorporate any design or photographic imagery to truly capture the essence of your band.

The ordering process is straightforward and efficient:

- Choose your custom size.

- Select your desired finish, such as pole pockets, eyelets, or stitched hems.

- Upload your artwork and provide any additional notes or instructions for our pre-press team, such as background colour or logo placement.

We at Banner World pride ourselves on producing high-quality band backdrops, ensuring your band’s visual presence is as impactful as the music itself. Whether you’re performing at a local pub or an energetic festival, our scrims will provide the perfect backdrop to enhance your performance and reinforce your band’s identity.

Band Backdrops, Custom Printed Solutions for the Music Scene

At Banner World, we understand the impact of visual elements on a band’s success and recognition. That’s why we specialise in printing vibrant and captivating band backdrops that enhance your stage presence and are eco-friendly and cost-effective.

Our custom-printed band backdrops are manufactured using fully recyclable polyester material, setting them apart from the cheap PVC alternatives found in the market. This sustainable and display-grade material ensures that our backdrops are durable while also being environmentally conscious.

Social media platforms such as Instagram, Facebook, YouTube, and Twitter are powerful channels for promoting your band’s name and brand. We recognise the potential of these platforms and strive to design backdrops that create a buzz among your followers while giving fans the opportunity to share and promote you.

With full-color printing, we provide our clients with photographic quality designs that can be manufactured at any custom size. For optimal impact, we recommend you make your logo big and bold, placing it above the center so it remains visible and unobstructed by the band members and their instruments.

We offer an easy step-by-step ordering process for our clients. To order your band backdrop:

- Choose your custom size.

- Select your finishing touches (pole pockets, eyelets, stitched hems, etc.).

- Upload your artwork and add any notes for our pre-press team (background color, logo positioning, etc.).

Our band backdrops are perfect for a variety of settings, from small pub gigs and club shows to major festivals and venues. Whether you are a wedding band, a retro rock group, or an emerging artist, our backdrops will create the energy and excitement necessary to engage your audience.

Moreover, having a professional backdrop raises your credibility as a band and can lead to better opportunities and partnerships, including deals with companies, sponsors, and organisers. Investing in a high-quality band backdrop will elevate your image and provide long-term benefits for your career.

Conclusion

In conclusion, we at Banner World are committed to delivering top-notch custom backdrops crafted from sustainable and fully recyclable materials. Our band backdrops enhance your stage presence, enrich your event, and contribute significantly to your band’s promotion on social media platforms. With our easy ordering process and instant pricing tool, you’ll receive the perfect backdrop tailored to your unique vision and creative expression.

Delivery

We deliver your Band banners in 5-6 working days from your banner order, payment and approval of artwork.

3 reviews for Band Banners and Backdrops

Troubadour (verified owner) –

Awesome backdrop just arrived, blown away with the quality, many thanks!

Abbalicious (verified owner) –

Our artwork was not too great but Banner World revamped it and made a brilliant stage backdrop for us. It’s easily the best backdrop on our circuit and we have had many jealous comments from other bands! Job done!

DURAN (verified owner) –

Great Customer service, assisted us with the order process and banner delivered quickly, really happy with the quality of material, finishing and printing, will definitely use again.

Lindsey Newman-Wood (verified owner) –

Ordered a banner for my son’s band. Great experience. John made us aware that our image was not good enough quality so we had a chance to re-do it. It was delivered today and the boys are made up! Great quality and image.

Nancy Doll (verified owner) –

Thanks so much. An amazing backdrop at an unbelievable price! Really added to the atmosphere of our last gig.

The Novatones (verified owner) –

The Novatones new stage backdrop is awesome, a brilliant job and the fans were all talking about it after our first gig with it at Talking Heads Southampton.

CGain Marketing (verified owner) –

These are the best made and the best finished band banners available. Really professional looking.

Based on 113

Google Reviews