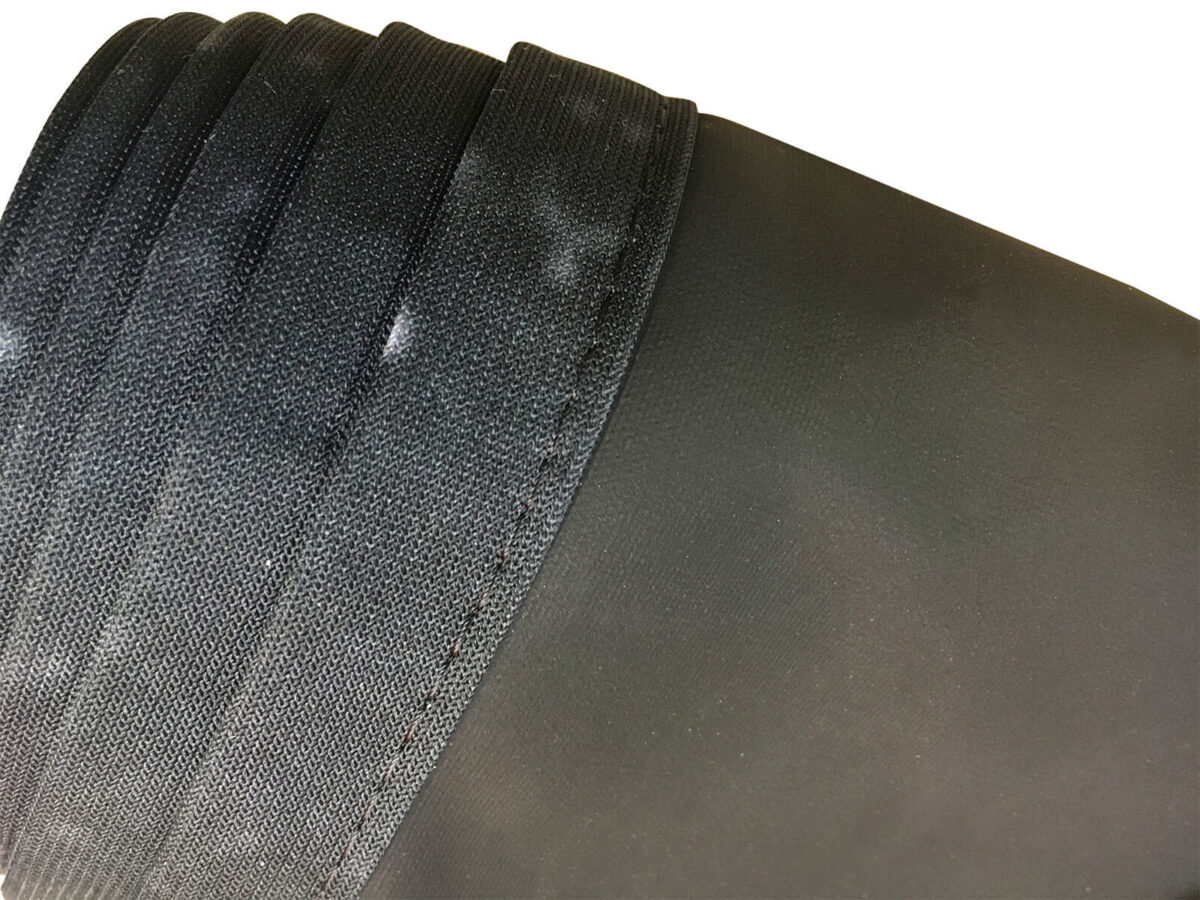

Blockout Band Banners and Backdrops which let no light through. 240gsm flexible fabric with a non-reflective finish. Water repellent. The black resin backing prevents light show-through from the rear.

We Print our blackout band banners using dye-sublimation technology. Dye sublimation prints colours are which are deep, vivid and vibrant. This printing technique engrains the ink to the material, meaning it can last for years.

Edges free of finishing are all hemmed as standard. Hemming prevents the material from fraying. We use specialised plastic eyelets to avoid damaging the fabric. Prices of our band banner include free finishing.

The material can be folded and packed away small, making it easy to store and transport.

Why Choose a Blockout Band Backdrop?

Blockout backdrops are ideal if you require no light show-through from behind your banner. The back of this material is a black latex resin which prevents light from showing from behind. Ideal if your backdrop is in front of intense lighting or erected against a window.

Also used where existing graphics need covering up, or where framework needs hiding.

Blockout Band Backdrop Specifications

- 240gsm polyester/resin fabric material

- Flame retardant with fire certificate available

- Tight weave white face fabric for stunning colour reproduction

- Professionally finished to your specification

- Maximum size in both dimensions without a join = 2.6m to 2.9m depending on finishing

Design your Band Backdrop in Full Colour

We print from your artwork – this can be your band logo or other design, including photographic or illustrated backgrounds. Thousands of high-resolution backdrop themes and ideas are available from image banks such as the Adobe Stock Library for minimal cost.

Our band banners will get you noticed! We also produce fantastic, band scrims, stage backdrops and exhibition displays. Banner World also manufactures printed theatre backdrops, podium backdrops and point of sale displays. We print these using dye-sublimation technology to provide eye-popping, vibrant colours and photo-quality images. We print fabrics on rolls up to 3.2m wide to provide huge seamless panels. Do you require a huge backdrop? We can create massive backdrops by stitching sections together.

Flame Retardancy Certificate

Our Fire Certificate for this product is unique in the industry in that we have our fabrics tested for flame retardancy after printing. Many venue safety officers will now not accept a generic fire safety certificate if it is just for the base fabric. Tested to the highest UK standards, our backdrops surpass BS5867-2: 2008: Type B.

Backdrop Options

We can also make even cheaper band banners and stage scrims from standard PVC or Mesh banner material. Although PVC and mesh do save on initial cost, they are not an ideal solution. Larger cheap band banners are more difficult to pack without creasing, take up more storage room and will not look as good for as long.

Need a Backdrop Banner Stand? Check out our new product here.

Blockout Backdrops in Action

We recently produced some 5m x 3.5m blackout fabric curtains for the 2018 BBC Get Inspired Awards, check the video here.

Design Guide for Band Backdrops

Set your dimensions correctly

Please set your artwork to the correct proportions of your final printed band banner. We do not require any bleed on the artwork for a printed backdrop. If necessary, you can set your artwork to scale.

Set the correct CMYK colour settings

Please make sure that you set your colour settings to CMYK. Our backdrop banner printers use a full-colour dye-sublimation printing process which works using cyan, magenta, yellow and black inks. Files that are sent to use using an RGB setup will be changed automatically. Sometimes this can make the colours on your printed backdrop seem weak & washed out. We will check for this before printing and contact you if required.

Position of eyelets on your Printed Band Banners

Please leave a clear area of approx 50mm inside the edge of the banner. Background colour/images are excellent. The eye hole apertures can obscure just no important text elements, small print or logos as these. Around our band banners, we will add hem and eyelets unless otherwise stated. It is not advised to have just fixing holes (without the hem) as this can cause the material to rip.

We space our eyelets approx every 500mm apart unless otherwise stated. Holes usually are evenly spaced so eyelet spacing might vary slightly on different sizes of banners.

Pole Pockets on Band Banners

We can finish your band banners with pole pockets if required. Please make sure when ordering you create the artwork to the size you require. Standard scaffold tubes are a 150mm flat pocket size to fit comfortably with plenty of space as to not cause to much tension on the pocket seam. Coloured background and/ images or patterns are perfect. Just keep clear of text or vital information. Check here for more information on pole pockets and how to design for them.

Band Banner Design Principles

For band banner design it is always important to consider viewing distances. Design your artwork to give the highest possible impact. Contrasting colours will give your banner much more clout than washed out subtle colours.

Also, think about text sizes. The larger the text, the more it will be viewed from a distance. Use upper and lower fonts. Look at road signs as they are all in upper and lower type rather than all capitals. Subconsciously your eyes will read upper and lower (sentence case) — font type. Usually, clearer fonts work better than stripy unreadable fonts. Look at the backdrops for the prominent performers – they often display the band name.

Less is more, cramming every little bit of information onto your band backdrop banner probably isn’t a good idea. Remember to use areas of space and give your design space to breathe. The best backdrops are always simple and straight to the point. Remember your average viewer needs to read your message in 3 seconds or less.

1 review for Blockout Band Banners and Backdrops

Amy Morican (verified owner) –

Great Band Banner and excellent service! responded to emails quickly and delivery was within my timescale! Would recommend and definitely use again!

Based on 113

Google Reviews