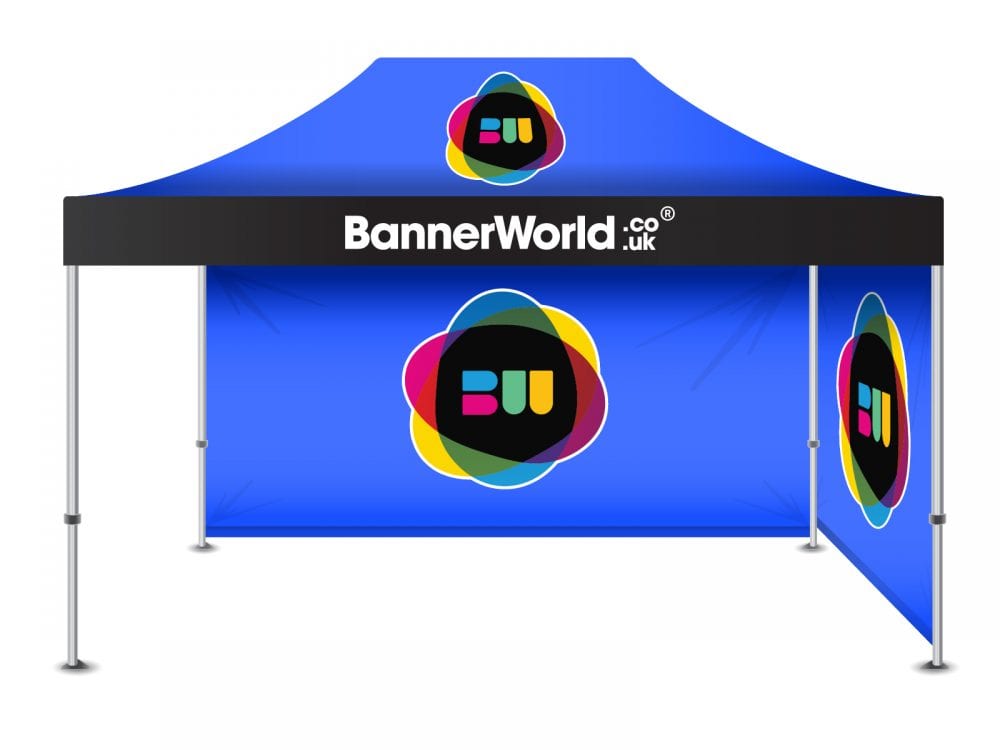

4.5m x 3m branded gazebo

4.5m x 3m branded gazebos are a fabulous solution for branding at any event. Our branded gazebo frames manufactured from aluminium with a double hexagonal 40mm profile makes them super durable and class-leading. Complimenting our tent frames, we print our fabrics using the latest in full-colour printing technology. Our tent material is waterproof, heavy-duty and fade-resistant, meaning it will keep performing while looking fantastic. Use our Gazebos at outdoor or indoor events.

High quality branded Gazebos

Our branded gazebos are the perfect solution for professional branding at any event, trade show or festival. Using the latest class-leading aluminium frames and fabrics, you can be sure that you are buying the best value Gazebo on the market. While other competitors offer lower quality items, we only use the best fabrics and gazebo frames which means we offer the best value for money on top quality printed gazebos.

Easy to order

Use our on-page gazebo builder to configure your tent easily. Select the number of frames which come complete with a fully printed roof. Then select the walls you require. The walls you choose will depend on the intended use of your Gazebo. We offer the options of half-height walls and full-walls which are available in the following options

• Inside printed. Meaning branding shows on the inside

• Outside printed. Branding is visible on the outside

• Double-sided printed. Branding shown on both sides

Tent frames

Our gazebo frames use only the best materials and high-quality components. Made from mostly all aluminium which is the best material as it offers lightweight construction a third lighter than steel which means the integral structures can be thicker, creating much-needed rigidity. Our frames use a 40mm double hexagonal profile. Hexagonal tubes increase the strength of the legs of the frame even further making them strong and stable. The aluminium is jointed together using top quality High-Density Polyethylene plastic components giving super durability and life expectancy.

Sizes

We offer a range of gazebo sizes: 3m x3m, 4.5m x 3m and the range-topping 6m x 3m. You can create larger gazebos by standing multiple tents next to each other, which makes a larger area.

Tent fabric

Our fabrics are an industry-leading printable tent material, and we print the material using a high quality, high-resolution dye-sublimation print method. The 325gsm tent fabric is 100% waterproof and has an inbuilt waterproof membrane.

Printing gazebos

We print onto the tent fabric with our full-colour dye sublimation print machines. Dye sublimation offers sublime photographic quality printing to large scale graphics, which means we can print any design onto our tent fabric, giving you endless design possibilities.

Carry case

Each gazebo frame comes complete with a heavy-duty carry bag. The carry bag features wheels for easy transportation.

Tools

Each gazebo frame comes with four durable tethering ropes include ground pegs and a hammer.

Tent assembly

When erecting your Gazebo, you will need at least two people to do this, but four people are much better as you have one person in each corner. Setting up your tent can be completed within a few minutes, pulling the frame up and out from the corners. Ideally, you should roughly position the roof and place each corner on the outer corners of the tent frame before extending the structure altogether. Extend the frame to 30-50% of its size and position the fabric roof in its corresponding corners. Once you have placed, the corner begins to pull out the corners of the frame. If there are two people, then pull out the frame and work diagonally so one person in each diagonal corner. Switch from corner to corner until you feel extend the structure to its maximum. Then you can start to pull up the canopy struts which will click into place once you have fully extended the canopy. Once you have erected the roof, you can adjust the legs. The legs have four height options and, push in the button to allow the poles to slide to the next height selection and click into place. Use the corner straps to wrap around the top corners on the inside of your roof. Also, use the tabs of velcro to wrap around the inside of the frame of the roof. You have now completed building your gazebo frame.

How to attach the fabrics to your Gazebo

The full fabric walls have velcro along the top edge, which connect to the velcro on the inside of the roof fabric. Position the material and then fasten the velcro. Once the roof velcro is attached then wrap the velcro tabs around the legs. Half walls come with a rail for connecting to the frame. Thread your pole through the top pocket and attach to each leg. Use the velcro side fasteners to secure your graphic to the legs by wrapping around them.

You must be logged in to post a review.