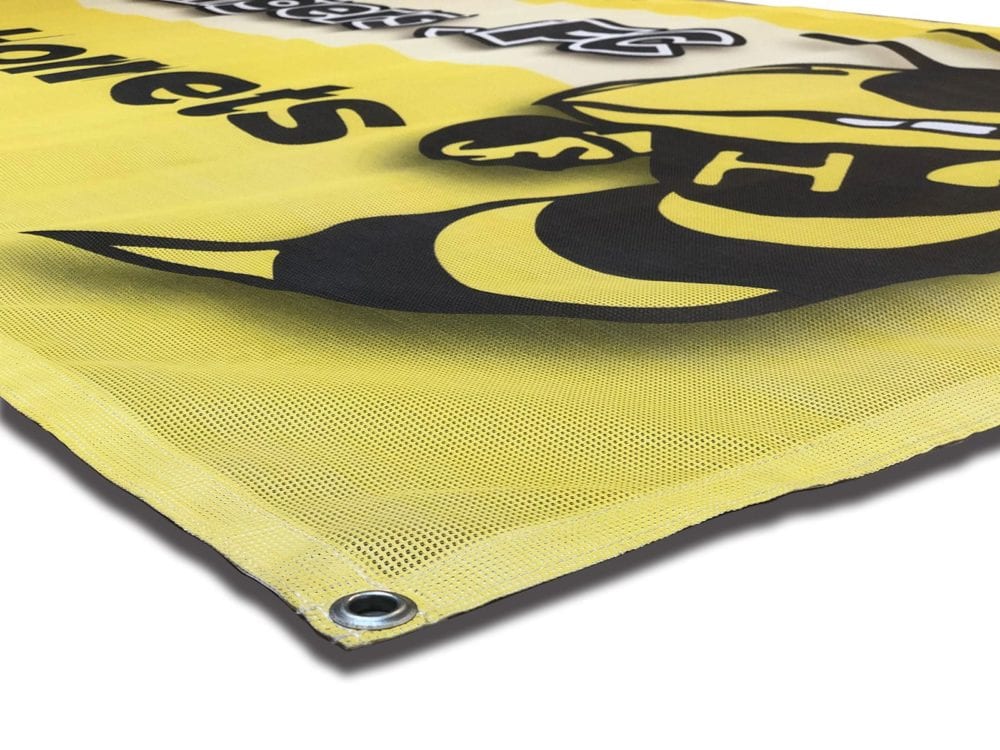

Introducing the Eco Mesh Banner from Banner World – the ultimate choice for eco-conscious businesses seeking superior advertising solutions. Crafted from 100% polyester mesh, this PVC-free banner offers a sustainable alternative without compromising on quality or durability.

Key Features:

- Eco-Friendly Composition:

- Made from 100% polyester, ensuring a fully recyclable and environmentally responsible product.

- PVC-free, reducing harmful environmental impacts and promoting sustainable advertising practices.

- Superior Print Quality:

- Compatible with Dye-sub direct and Dye-sub transfer printing, allowing for vibrant, high-resolution graphics that captivate audiences.

- Semi-glossy finish enhances visual appeal, making your advertisements stand out.

- Versatile Applications:

- Perfect for a variety of uses, including scaffold hoardings, TV backdrops, hanging displays, and large-format advertisements.

- The slight stretch feature ensures it fits perfectly as frame and pop-up materials, offering flexibility for different display requirements.

- Exceptional Durability:

- Warp-knitted, 2-bar weave method provides robust tensile and tear strength (469X737N/5cm and 125X163N respectively), ensuring long-lasting performance even in challenging conditions.

- Flame resistant, meeting DIN 4102-1-B1 and NFPA 701 Test1 standards, making it safe for various indoor and outdoor applications.

- Impressive Size and Customisation:

- Available in widths up to 5 meters (197 inches), offering expansive coverage for large advertisements.

- Standard lengths of 50 meters (55 yards) provide ample material for extensive campaigns.

- Temperature Resistance:

- High shrinkage resistance (≤3% at 210°C, 30s) and a yellowing temperature of ≥210°C, ensuring the banner maintains its integrity and appearance under varying environmental conditions.

Why Choose Eco Mesh Banner from Banner World?

- Sustainable and Ethical: Contribute to environmental conservation with a product designed for minimal ecological impact.

- High Performance: Enjoy durable, high-quality advertising material that withstands wear and tear, providing excellent value for money.

- Versatility: Adaptable for multiple advertising and display applications, meeting diverse business needs.

1 review for Eco Mesh Banner

Pete Owens (verified owner) –

good

Based on 113

Google Reviews