Custom printed fabric

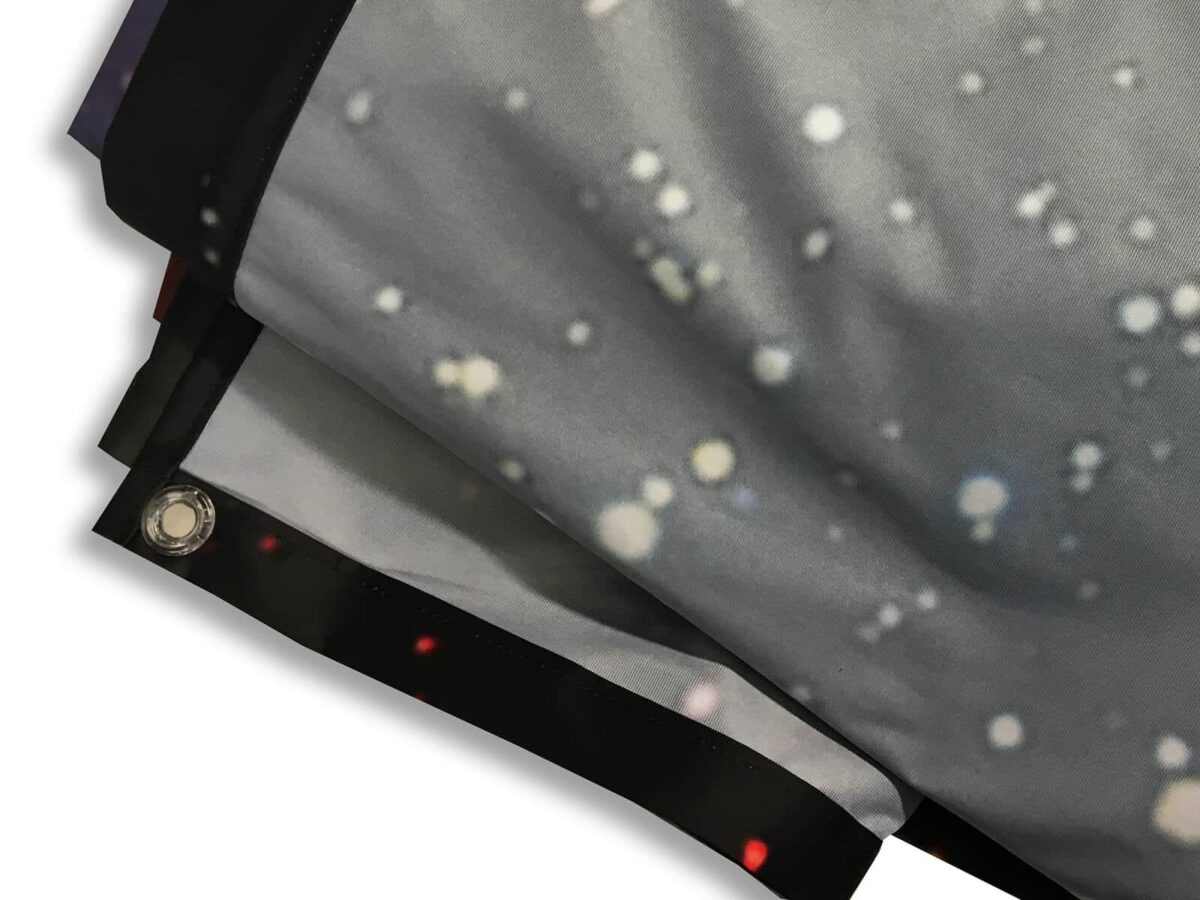

Polyester 210gsm is a custom printed fabric. The base material is white, and we print in full colour, creating stunning results. With ever-evolving large format printing technology, we can print onto a range of fabrics which wasn’t possible a few years ago. The technology means we create custom one-off printed fabrics with many uses. The material is lightweight and easy to handle. Because polyester 210 is a fabric ist easily foldable for storage. Even large printed stage curtains take up very little storage space.

Printed fabrics for crafts

We print fabrics for crafts and artists. If required, we can supply you with printed fabric which is left on the roll so unfinished. If you need a one-off design printing onto fabric for a project, then look no further. We offer a range of fabrics including Satin, Light-Stop fabric, Water Proof fabrics, Veil, Canvas and many more.

Quality Printed Custom Fabric

A tight weave in this fabric allows for stunning, high-resolution printing using dye-sublimation. The Dye Sublimation process works by fusing the dye to the molecules of the polyester fabric. This process means that colour cannot run and also creates a fade-resistant print.

Fire-rated printed fabrics

Our polyester fabric is fire-rated and complies with all EU and UK fire regulations. Our fire certificate is available for download at the top of this product page.

Satin custom fabric printing for photoshoots

Polyester 210 is a satin product and is non-reflective. Being non-reflective and anti-glare makes this material brilliant in front of a camera lens. Polyester 210 is the perfect material for use on the stage, photoshoots, or even red carpet events. If you need to a backdrop for photography, then look no further than polyester 210. If you have issues with light sources from behind you photoshoot, it’s worth considering a black-out material for photoshoots. Our block our backdrops have a special black resin liner on the back of the cloth. This liner is a light-stop barrier meaning no light can travel through. Our light-stop product is brilliant for use over windows or when rear lighting is a problem.

How can we print quality custom fabrics so cost-effectively?

We print our fabric using the latest advances in fabric printing technology. Most of our print jobs are batch-processed. Because we batch large quantities of jobs together, we can print with tighter margins than our competition. We produce large format printing from all over Europe. Your job, even if it is a one-off event fabric, will be printed alongside dozens or hundreds of others.

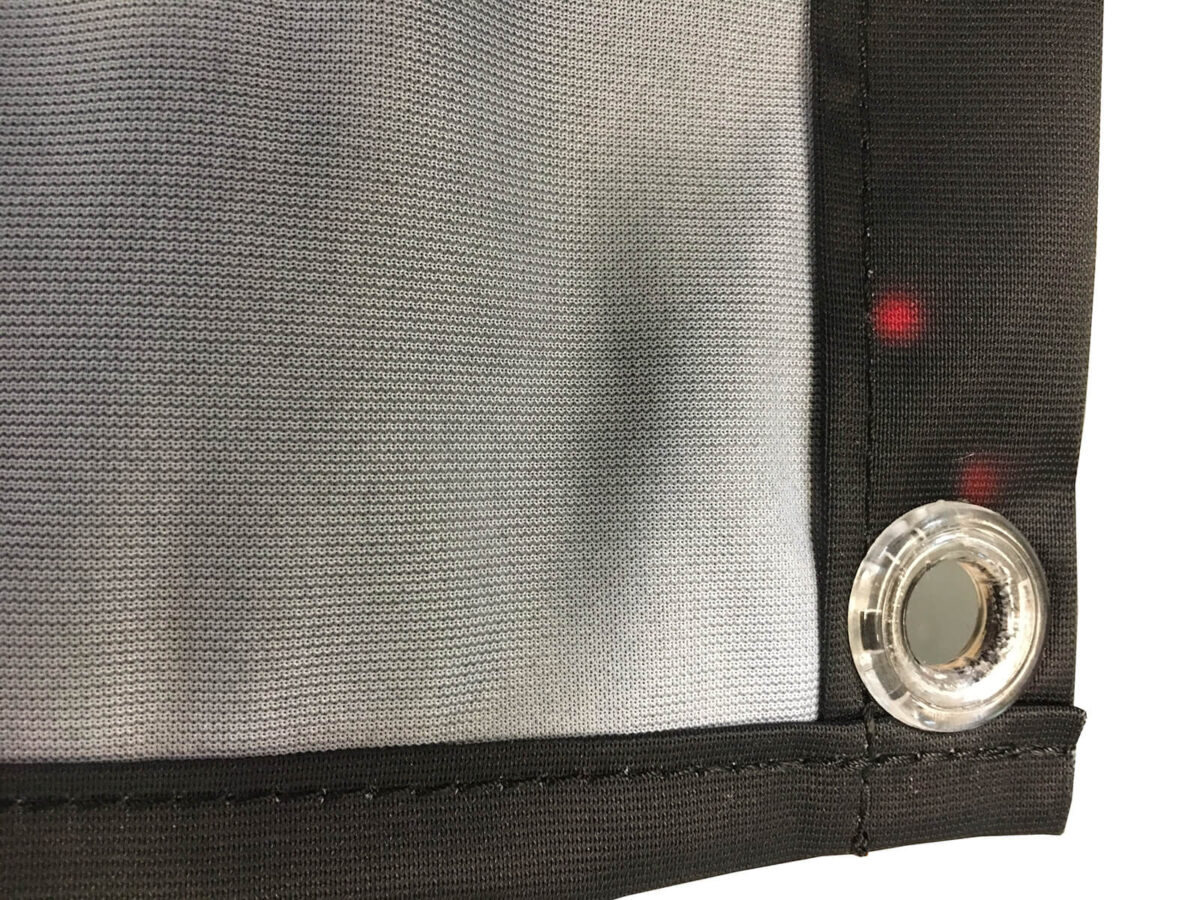

Custom printed fabric Finishing

We offer a range of finishing for your fabric. We offer hem and eyelets, pole pockets, velcro and a range of flag finishing option. The flag finishing option is not available on the product; however, if our required printed flags, then we have a range of flags for you to browse.

How large can you print a custom fabric?

We print Polyester 210 to whatever size you like. The polyester fabric comes on rolls up to 3m wide. Larger prints will contain seams to join the fabric together. Over the years we’ve produced some quite amazing sized fabrics with some over 100 metres in length.

You must be logged in to post a review.