Making PVC Banners for the trade is a large-scale operation involving quality materials, industrial superwide printers and precise finishing solutions. We offer a wide range of banner printing products. All…

Making PVC Banners for the trade is a large-scale operation involving quality materials, industrial superwide printers and precise finishing solutions. We offer a wide range of banner printing products. All of our products use high-quality banner materials and inks. So how do we make the perfect banner? And what material do we use?

PVC Banner Materials

We offer several PVC banner materials, all designed for particular uses.

Making PVC banners that last

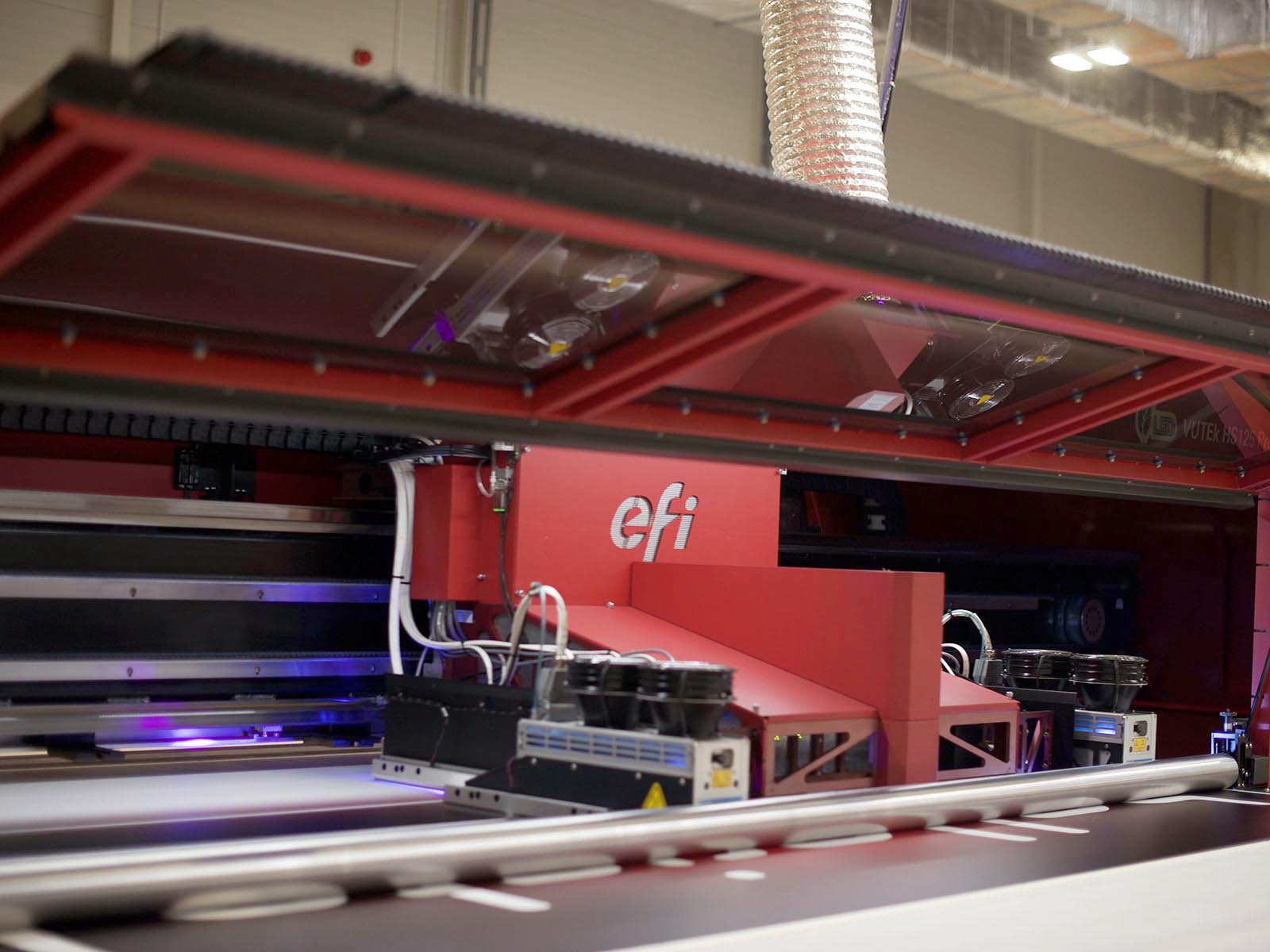

We manufacture banners to the highest standards using the latest printing technology. So how are banners made?

We print your banners.

We print your artwork onto a range of high-quality banner material. Before printing, we would add any additional material for finishing. Adding extra material for hems or pockets. Depending on the material will define which process we would use. We print banners using either a UV, solvent or dye-sublimation print process.

Finishing your banners.

Firstly your banners are cut to size. Once your banner is trimmed, we would either weld or stitch your pockets. Weld nr stitching depends on the requirements and the material spec. For example, fabrics and eco banners require stitching as welding isn’t possible. In some instances, a reinforced hem is required for extra durability. The reinforced hem features a weld and also stitching for added durability.

Eyeletting your banner

We use a pneumatic eyeletting machine to place the banner eyelets. Banners with eyelets are our most popular product. The banner eyelet machine places a solid eyelet through your banner, which creates strong fixing points. Banner eyelets are positioned every 500mm unless otherwise stated.

Event Banner

Event banner is the perfect material for short term events, shows and promotions. Most events are only short term, so our event banner is a cost-effective solution for any short term banner. Even at 510gsm weight, our Event banner is the lowest cost trade banner. Suitable for short-to-mid-term use outdoors (up to 6 months). Printed in full colour on rolls up to 2.5m wide. Larger banners require our Premium PVC Banner material. Finished with hems, eyelets and pole pockets.

Premium PVC Banner

Our most popular PVC banner material at 500gsm. Making PVC Banners using our premium banner material is recommended for large outside banners. The nylon weave inside the banner makes this banner material much stronger than standard banner printing. Super-strong and suitable for long-term outdoor use, the material is much more durable than event banner material. Printed at up to 5m wide, larger banners can be welded together in panels or sections. Finished with hems, eyelets and pole pockets.

Double-Sided Blockout

At 650gsm, Double Sided Blockout is our toughest and strongest PVC banner material. Used for all double-sided banners and premium single-sided banners.

Mesh Banners

Mesh banners are used outdoors, where wind-loading may be an issue. Tiny holes in the fabric allow wind to pass through. These are commonly used for fence banners, scaffold banners and building wraps.

Eco-Friendly Banners

Making PVC Banners that are good for the environment. We also produce a range of PVC-free 100% Recyclable Banners, ideal for environmentally-conscious projects.

PVC Banner Printing

As standard, our PVC Banners are printed using the latest superwide format UV machines. Optionally we can also use eco-solvent machines or HD Latex. Fabric banners use a specialised dye sublimation process which dyes the fabric into the desired colours. Dye sublimation banners can be used as indoor displays or outside and are machine washable.

PVC Banner Finishing

We offer hems, eyelets and pole pockets as standard on PVC Banners. Options include solutions such as Kedar, Velcro and Omega Tunnels. We use machinery such as heavy duty welders and automatic eyeletting machines.