Mesh scaffold banners allows air to pass through the face of the banner, reducing wind loading and ensuring that the banner stays in place. We offer a variety of finishing options, including pole pockets that are high frequency welded or hemmed with eyelets. For clients who require a higher level of strength, we also offer reinforced pockets that are high frequency welded and then stitched over the top.

At Banner World, we are committed to providing our clients with the best possible service and products. Our mesh scaffold banners are just one of the many options we offer to help our clients promote their businesses and events.

Scaffolding Mesh Banners

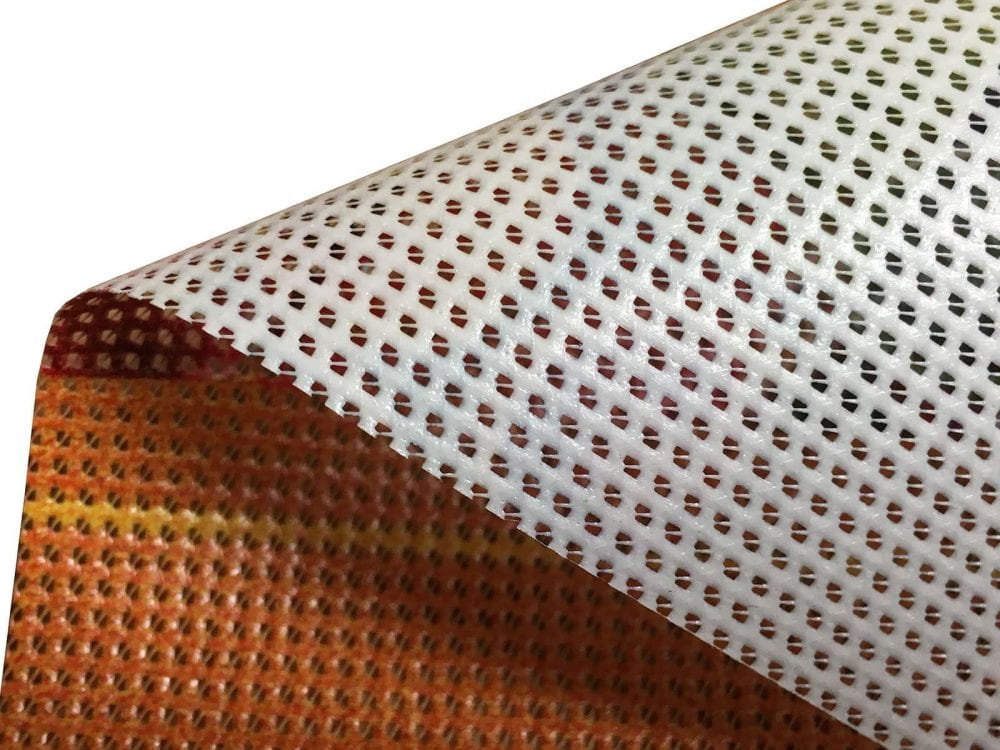

At Banner World, we offer high-quality banner printing services for our clients. We specialise in printing mesh scaffold banners using the latest UV print method. Our mesh banners are single-sided with a white, unprinted reverse and are designed to let air through the face, which reduces wind loading. We offer a range of finishing options for our banners, including pole pockets that are high frequency welded or hem and eyelets. We also offer reinforced pockets that are high frequency welded and then stitched over the top to offer a higher level of strength. We have a variety of other materials for our scaff banners, including PVC and fabric. Our printers can print banners up to any size on our 5-meter wide machines. They are printed in full colour using UV print process.

Low-cost mesh scaffold banners

Benefits of Mesh Scaffolding Banners

Wind resistant

Mesh scaffold banners are designed to withstand strong winds, which means they add less wind loading to structures. Holes in the fabric create airflow and make mesh the ideal material for use on scaffolds.

Strong

The high-quality PVC mesh material used in the printing of mesh scaffold banners is incredibly durable and long-lasting. This means they can withstand the wear and tear of being used on scaffolds for extended periods.

Cost-effective

Mesh scaffold banners are a cost-effective way to promote your brand, products, or services. They are affordable to produce and can be used repeatedly, making them a great investment for companies looking to increase their sales and trade.

Eye-catching

The full-colour printing process used for mesh scaffold banners ensures that they are bright and eye-catching. Our print process makes them an effective way to capture the attention of your audience and engage them with your brand.

Versatile

Mesh scaffold banners can be produced in any size, which means they can be used on scaffolds of any height or width. They can also be customized with pole pockets, hem and eyelets, reinforced pockets, and corner eyelets to suit your specific needs.

Weather-resistant

Mesh scaffold banners are designed to withstand harsh weather conditions, including rain, wind, and sun. The durability of mesh means they will remain in excellent condition for longer, providing excellent value for money.

Easy to install

Mesh scaffold banners can be easily attached to scaffold poles using the pole pockets, hem and eyelets, reinforced pockets, or corner eyelets. Being quick and easy to install will save you time and money.

Overall, using mesh scaffold banners for your scaffolding advertising banners and scaffolding signs is a smart strategy that can help you increase brand engagement, capture the attention of your audience, and ultimately make more money. With their wind resistance, strength, versatility, and eye-catching colours, mesh scaffold banners are an excellent material for banner printing that can help you achieve your marketing goals.

Custom scaffolding banners

Best scaffolding banners

Order scaffold banners in bulk

Mesh Scaffolding banner prices

Custom sized Mesh scaffold banners

PVC Mesh scaffolding banner finishing options

Our Products

At Banner World, we specialise in printing various banners, including mesh scaffold banners, PVC banners, vinyl banners, and event banners. We offer a range of finishing options to suit our clients’ needs, including pole pockets, hem and eyelets, and reinforced pockets.

Our mesh scaffold banners are a popular choice for clients who need to display their message on scaffolding structures. The mesh material allows air to pass through, reducing wind loading and ensuring that the banner stays in place even in windy conditions. We use a UV print method to ensure that our banners are durable and long-lasting.

We also offer double-sided scaffold banners, which are an excellent choice for clients who want to display their message on both sides of the scaffolding structure. Our double-sided banners are printed using the same UV print method as our single-sided banners, ensuring that the print quality is consistent across both sides.

In addition to our scaffold banners, we also offer Heras fence covers, which are a great way to promote your brand or message at outdoor events. Our Heras fence covers are made from high-quality materials and can be printed to any size or specification.

Mesh Material and Durability

At “Banner World”, we take pride in the quality of our mesh scaffold banners. Our banners are made from a durable and weather-resistant PVC mesh material, which is designed to withstand harsh outdoor conditions. The material has a weight of 330gsm, making it sturdy and long-lasting.

Our PVC mesh material is specifically chosen for its wind-resistant properties. The mesh design allows wind to pass through the banner, reducing the sail effect and preventing damage to the banner or the structure it is attached to. This makes our banners ideal for outdoor use, particularly in windy areas.

We use a UV print method to create high-quality, fade-resistant prints on our banners. This ensures that the banners maintain their vibrant colours, even after prolonged exposure to sunlight. Our banners are also waterproof, which means they can withstand rain and other forms of moisture without damage.

To further enhance the durability of our banners, we offer a variety of finishing options. Our banners can be finished with pole pockets, which are high frequency welded or hemmed and eyeleted. We also offer reinforced pockets, which are high frequency welded and then stitched over the top to offer a higher level of strength.

Overall, our mesh scaffold banners are designed to provide a durable and long-lasting advertising solution for our clients. We take pride in the quality of our materials and the expertise of our team, and we are confident that our banners will meet the needs of any outdoor advertising campaign.

Design Specifications

At Banner World, we offer a range of design specifications for our mesh scaffold banners. You can provide your own artwork, or use our online design facility to create their own unique design.

Our mesh scaffold banners are available in any size, and we use full-colour CMYK printing to ensure that your design is vibrant and eye-catching.

We accept artwork files in EPS, AI, PDF, high-res JPEG, and TIFF formats, and we recommend that your artwork be set with no bleed. Artwork should be between 75-150dpi for optimal printing results. We also offer reinforced pockets, which are high frequency welded and then stitched over the top to offer a higher level of strength. Pole pockets are also available, which are high frequency welded for added durability.

Our mesh material allows air to pass through the face, reducing wind loading and increasing the lifespan of your banner. This makes our mesh scaffold banners ideal for use in outdoor environments where wind is a factor.

Scaffold Mesh Banner Safety Features

At Banner World, we take safety seriously, and that’s why we offer a range of safety and resistance features for our mesh scaffold banners. Our banners are designed to withstand harsh weather conditions and reduce wind loading.

One of the key features of our mesh scaffold banners is the tiny holes that allow for air flow, reducing wind loading and the sail effect of the banner. This ensures that our banners are less likely to be destroyed by high winds and bad weather conditions.

In addition, our mesh scaffold banners are made from flame-retardant materials, providing an added layer of safety. This is particularly important in construction sites where safety is a top priority.

We also offer reinforced pockets for our banners, which are high frequency welded and then stitched over the top to offer a higher level of strength. This ensures that our banners are durable and long-lasting, even in tough conditions.

Overall, our mesh scaffold banners are designed with safety and resistance in mind. We take pride in offering high-quality products that are built to last and provide maximum safety for our clients.

1 review for Mesh Scaffold Banners

Richard Craig (verified owner) –

Superb service, sensible prices, friendly and helpful staff. love the scaffold banner looks fab and. is easy to transport. Will be using these guys again, for sure.

Based on 113

Google Reviews