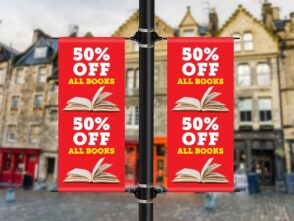

In today’s competitive event market, creating eye-catching and memorable promotional materials is key to a successful event. One popular and effective way to promote your event is through banner printing. With…

Read MoreArtwork Setup

Advice and guidance on how to set up your artwork for our large format digital printing processes.

Processes include Eco-Solvent Printing, UV Printing, Dye-Sublimation Printing and Latex Printing.

Our Guides look into how to get the best from every process.

Backdrops (19)

Banner World News (40)

Banners (30)

Cafe Barriers (8)

Chairs (2)

Construction Signage (12)

Dementia Friendly (5)

Environmentally Friendly (1)

Exhibition & Display (10)

Flags (13)

Heras Fencing Covers (5)

Large Format Printing (11)

Posters (3)

Product Guides (12)

Tablecloths (2)

Testimonials (6)

Vinyl Graphics (7)

Window Graphics Articles (3)